The Greatest Guide To Sandblaster For Sale

Wiki Article

Everything about Grit Blasting

Table of ContentsThe Single Strategy To Use For Grit BlastingWhat Does Sandblasting Near Me Do?An Unbiased View of Sand Blasting SandAn Unbiased View of Grit BlastingThe 45-Second Trick For Sandblaster For SaleExcitement About Shot Blasting Near Me

Damp rough blasting [edit] Damp unpleasant blowing up uses water as the fluid moving the abrasives. The advantages are that the water catches the dirt created, and also lubricates the surface area. The water supports the influence on the surface area, decreasing the removal of audio product. Among the original pioneers of the damp unpleasant process was Norman Ashworth that found the benefits of making use of a wet process as a solid option to dry blowing up.

Decreased impregnation of blowing up material into the surface, dirt decrease and the elimination of fixed stick can cause a really tidy surface - abrasive blasting. Damp blowing up of light steel will lead to instant or 'flash' corrosion of the blown up steel substrate as a result of the existence of water. The absence of surface recontamination also allows the usage of single equipment for numerous blowing up operationse.

Getting The Black Diamond Blasting Sand To Work

A version of wet blowing up is vapor blasting (or vapour blasting; U.K.). In this procedure pressurized air is added to the water in the nozzle generating a high speed mist, called "vapor". This procedure is even milder than wet blowing up, allowing breeding surfaces to be cleansed while retaining their capability to mate.Mixing particles with water significantly minimizes dirt. Bead blasting is the process of removing surface area deposits by using fine glass grains at a high stress without damaging the surface area. It is made use of to clean calcium down payments from swimming pool floor tiles or any type of other surface areas, remove ingrained fungi, and brighten grout color.

In removing paint for automobile body work, bead blasting is favored over sand blasting, as sand blasting has a tendency to create a better surface account than bead blasting. Grain blasting is commonly used in developing a consistent surface coating on machined components.

Grit Blasting Fundamentals Explained

The very first blast wheel was patented by Wheelabrator in 1932. Hydro blasting is not a type of abrasive blowing up as no unpleasant media is used. Hydro-blasting, frequently known as water blasting, is commonly used because it generally needs just one operator.This technique is excellent for cleaning internal and outside surface areas since the operator is normally able to send the stream of water right into places that are difficult to reach making use of other methods. An additional benefit of hydro-blasting is the ability to recapture as well as recycle the water, decreasing waste as well as mitigating environmental influence.

Greater stress are typically required. The most usual micro-abrasive blasting systems are business bench-mounted units containing a power supply and mixer, exhaust hood, nozzle, and also gas supply. The nozzle can be hand-held or fixture placed for automated procedure. Either the nozzle or component can be relocated in automated operation.

6 Simple Techniques For Pressure Washer Sandblaster

Automated blasting is frequently just an action in a larger automated treatment, generally including various other surface treatments such as prep work and covering applications. Care is typically needed to isolate the blowing up chamber from mechanical elements that may be subject to dust fouling. Dry-ice blasting [edit] In this sort of blowing up, air and also solidified carbon dioxide shot blasting grit are utilized.The air compressor provides a large volume of high pressure air to a solitary or multiple "blast pots". Blast pots are pressurized, tank-like containers, full of abrasive product, utilized to allow a flexible amount of blasting grit into the primary blasting line. The variety of blast pots is dictated by the quantity of air the compressor can give.

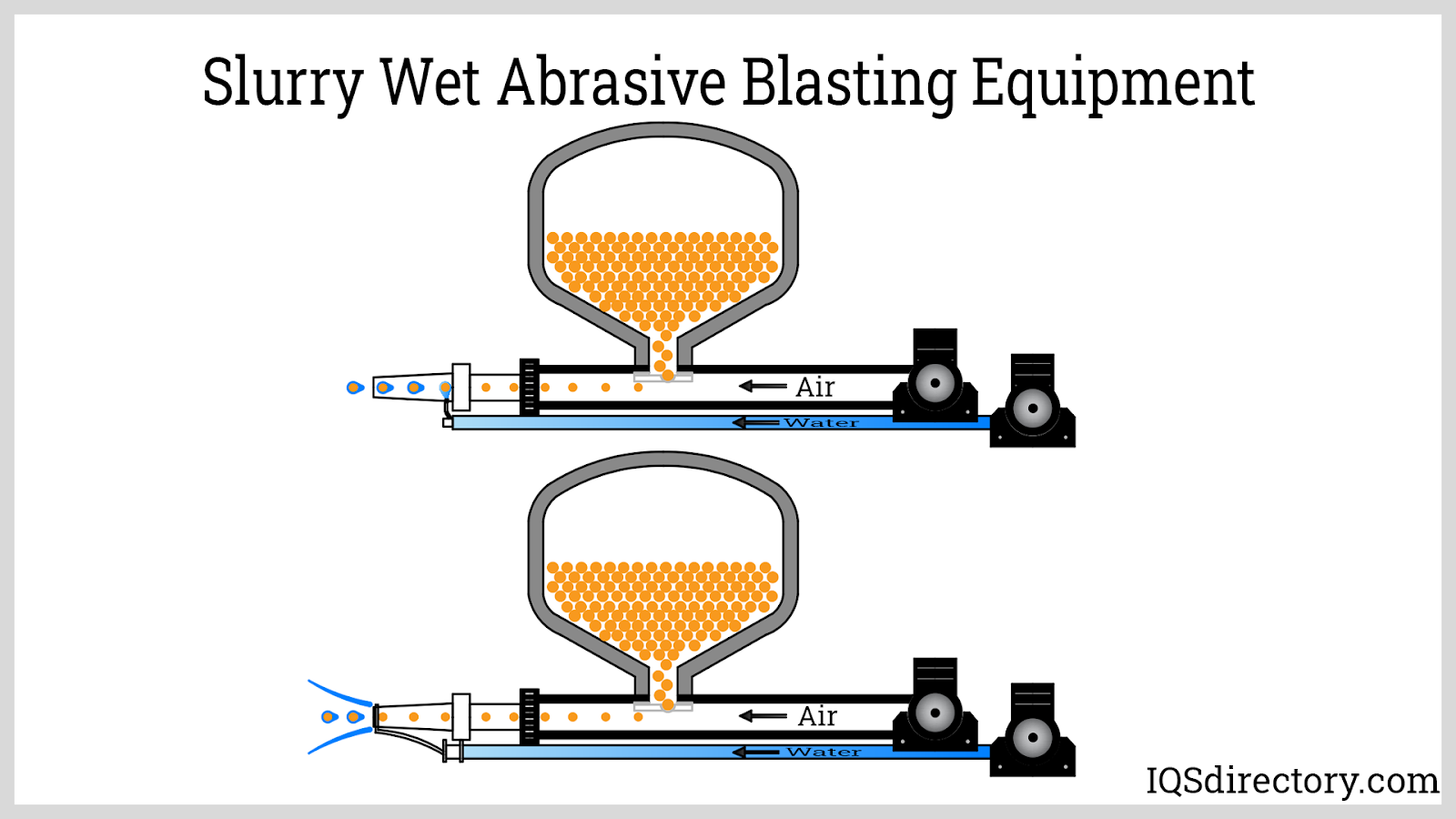

Others are receptacle-fed types making them light-weight and a lot more mobile. In damp blasting, the abrasive is introduced into a pressurized stream of water or various other fluid, producing a slurry. Wet blowing up is often made use of in applications where the marginal dust generation is preferred. Mobile applications might or might not recycle the rough.

Shot Blasting Near Me - An Overview

There are three systems normally used in a blast cupboard. 2, siphon and stress, are dry and also one is wet: A siphon blast system (suction blast system) utilizes the compressed air to develop vacuum cleaner in a chamber (called the blast gun). The adverse stress pulls rough right into the blast gun where the pressed air guides the abrasive via a blast nozzle.

Silicon carbide and also boron carbide nozzles are more wear resistant as well as are typically used with more difficult abrasives such as aluminium oxide. Low-cost rough blowing up systems as well as smaller sized cabinets use ceramic nozzles.

About Sand Blaster Harbor Freight

The vessel is pressurized to the very same pressure as the blast tube connected to the bottom of the pressure vessel. The abrasive is metered into the blast hose pipe and also shared by the pressed gas with the blast nozzle. Wet blast cupboards utilize a system that infuses the abrasive/liquid slurry right into a compressed gas stream.Report this wiki page